File Size: 4.01 Mb

Description

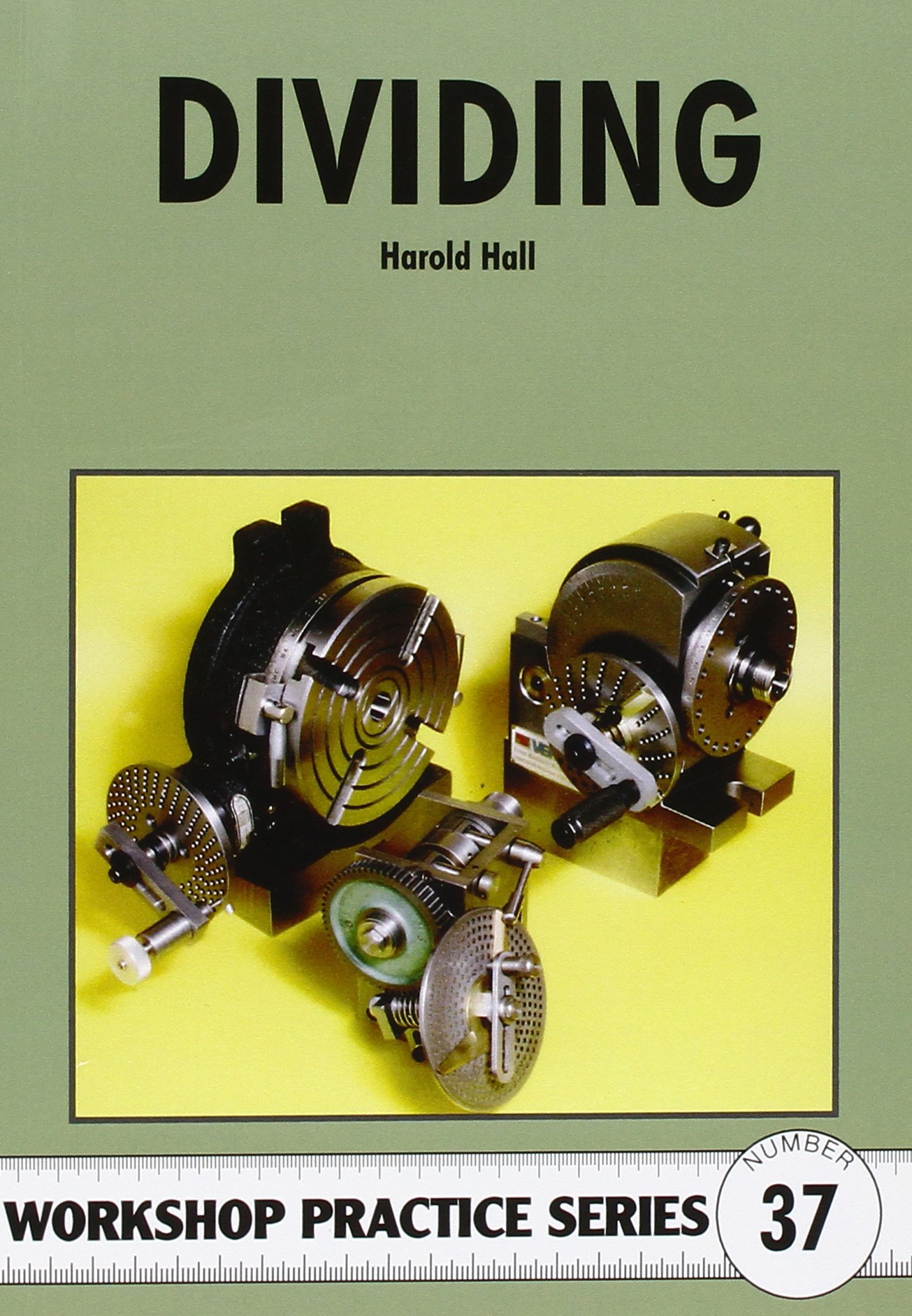

Faced with the prospect of machining a gear or gears for a project, many model engineers will be discouraged and will turn elsewhere for their next model. This need not be so, for the principles underlying gear cutting and many other aspects of engineering where an accurate division of circles is required are explained in depth in this book. Radial work on a metalworking lathe, such as the cutting of gearwheels or the drilling of holes on a set radius, calls for a method of precisely spacing the cuts. This skill is known as Dividing. The principles underlying this aspect of engineering are explained in depth in this book. It covers the subject of Dividing, dealing with the many methods that can be adopted: from simple applications without specialised equipment to the use of a semi-universal dividing head and a rotary table. The mathematical aspects of dividing are also covered but at a level that will be understood easily by a model engineer. Dividing equipment is relatively expensive, so two fully-detailed designs are included for dividing heads: a basic unit and the equivalent of a commercial semi-universal head.

Content:-

Chapter 1: An introduction to Dividing

Chapter 2: The Machinery. Discusses the major items of equipment, Dividing heads, Rotary tables,

Indexers, etc.

Indexers, etc.

Chapter 3: The Methods. Explains how to use the equipment in Chapter Two to achieve the required

result. Also explains though how even complex dividing can be achieved using no other equipment than that normally found in the:__workshop, typically the lathe and milling machine.

result. Also explains though how even complex dividing can be achieved using no other equipment than that normally found in the:__workshop, typically the lathe and milling machine.

Chapter 4: The Mathematics. Whilst the tables provided with a dividing head, or those published in

this book, will provide the information for most applications, occasionally recourse to calculation may be necessary. This chapter explains the process, fortunately, the mathematics is not complex.

this book, will provide the information for most applications, occasionally recourse to calculation may be necessary. This chapter explains the process, fortunately, the mathematics is not complex.

Chapter 5: Holes on a Pitch Circle Diameter (PCD) Explains the mathematics for placing holes on a

PCD using a milling machine's X and Y table movements and their calibrated leadscrew dials. Also shows how using a computer spread sheet program can be used to limit considerably the work involved

PCD using a milling machine's X and Y table movements and their calibrated leadscrew dials. Also shows how using a computer spread sheet program can be used to limit considerably the work involved

Chapter 6: Shop Made Simple Dividing Devices. Some simple devices that will enable dividing

activities without the need for a dividing head.

activities without the need for a dividing head.

Chapter 7: Shop Made Basic Dividing Head. A simple dividing head that is easy to construct, and for most, will be adequate for all the dividing tasks required in the workshop.

Chapter 8: Shop Made Full Function Dividing +lead. A dividing head that is more adaptable than a

commercially available semi-universal head and providing a wider range of divisions. It is not over complex to make and would be a very satisfying project to complete.

commercially available semi-universal head and providing a wider range of divisions. It is not over complex to make and would be a very satisfying project to complete.

Author Details

"Harold Hall"

You May Also Like These E-Books:-

why i cant download all file?

ReplyDelete